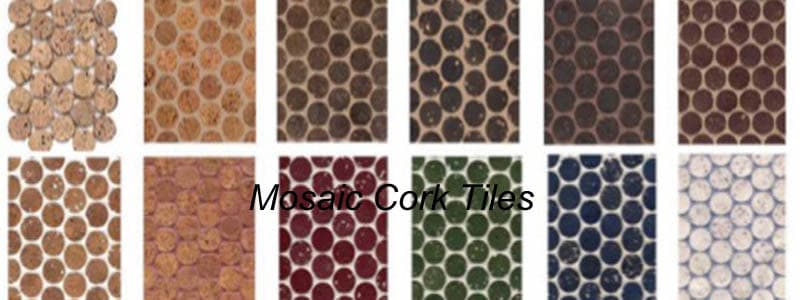

| Mosaic cork tiles are a beautiful alternative to other types of mosaic tiles (wood, porcelain, stone, or ceramic) or to traditional cork tiles (floating or glue-down). They require a bit more work to install them because of the need to caulk or grout around the cork disks, but the effort is well worth it. It’s a beautiful look for any home or office. |

To make the biggest impact upon the look and feel of your home, most people think that they have to remodel the entire home, including changing the paint color, furnishings, curtains, floorings, and more, but this is not usually the case.

A simple way to update the look and feel of a room may be as simple as changing the flooring. One way to add warmth and comfort to a room is to install mosaic cork tile. Cork is not as well known as hardwood, but it can offer the same warmth and classic style, as well as new comfort and texture.

Check out our best reviews and comparisons of cork floor tiles here at The Flooring Lady!